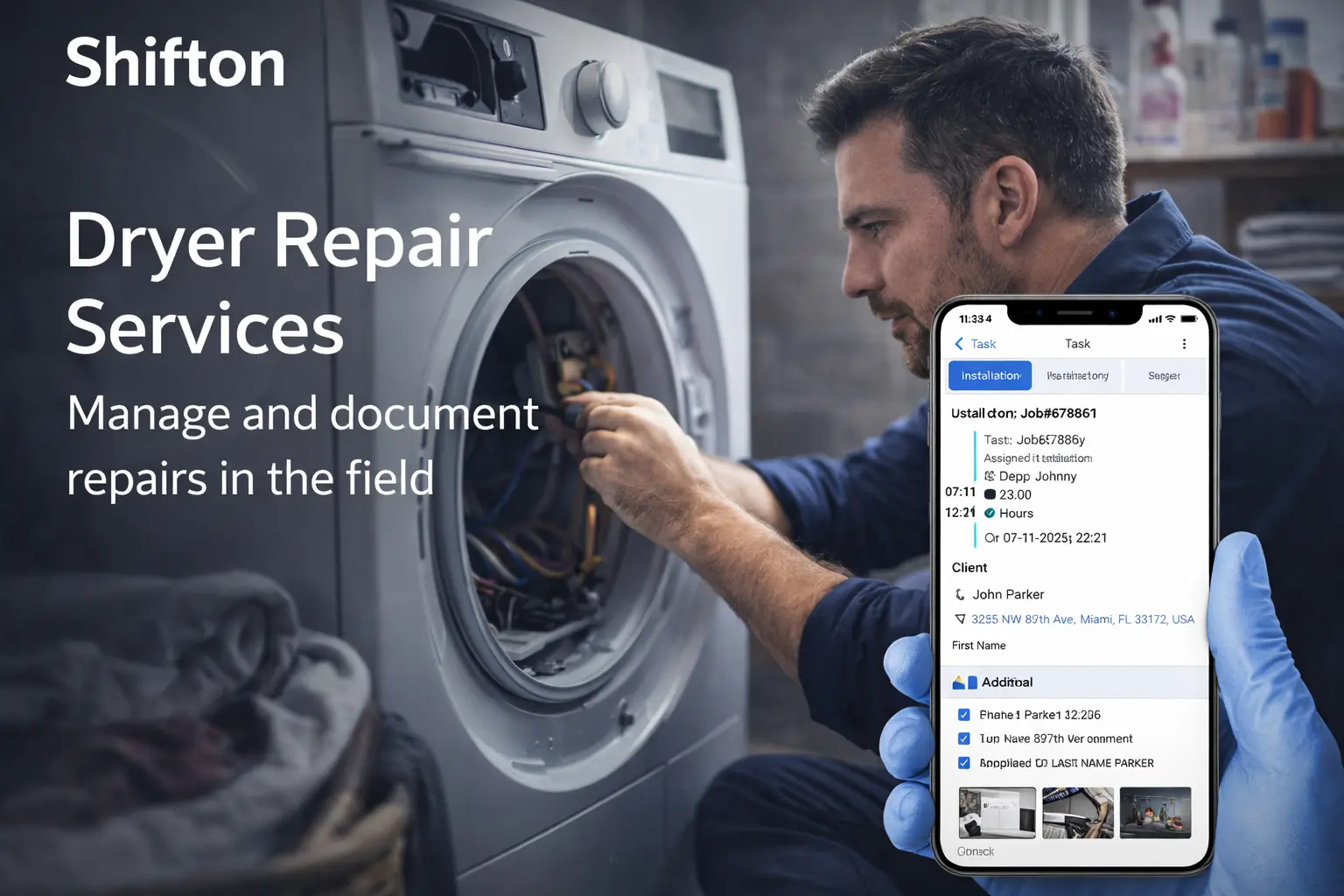

Real-Time Control for Laundry Operations

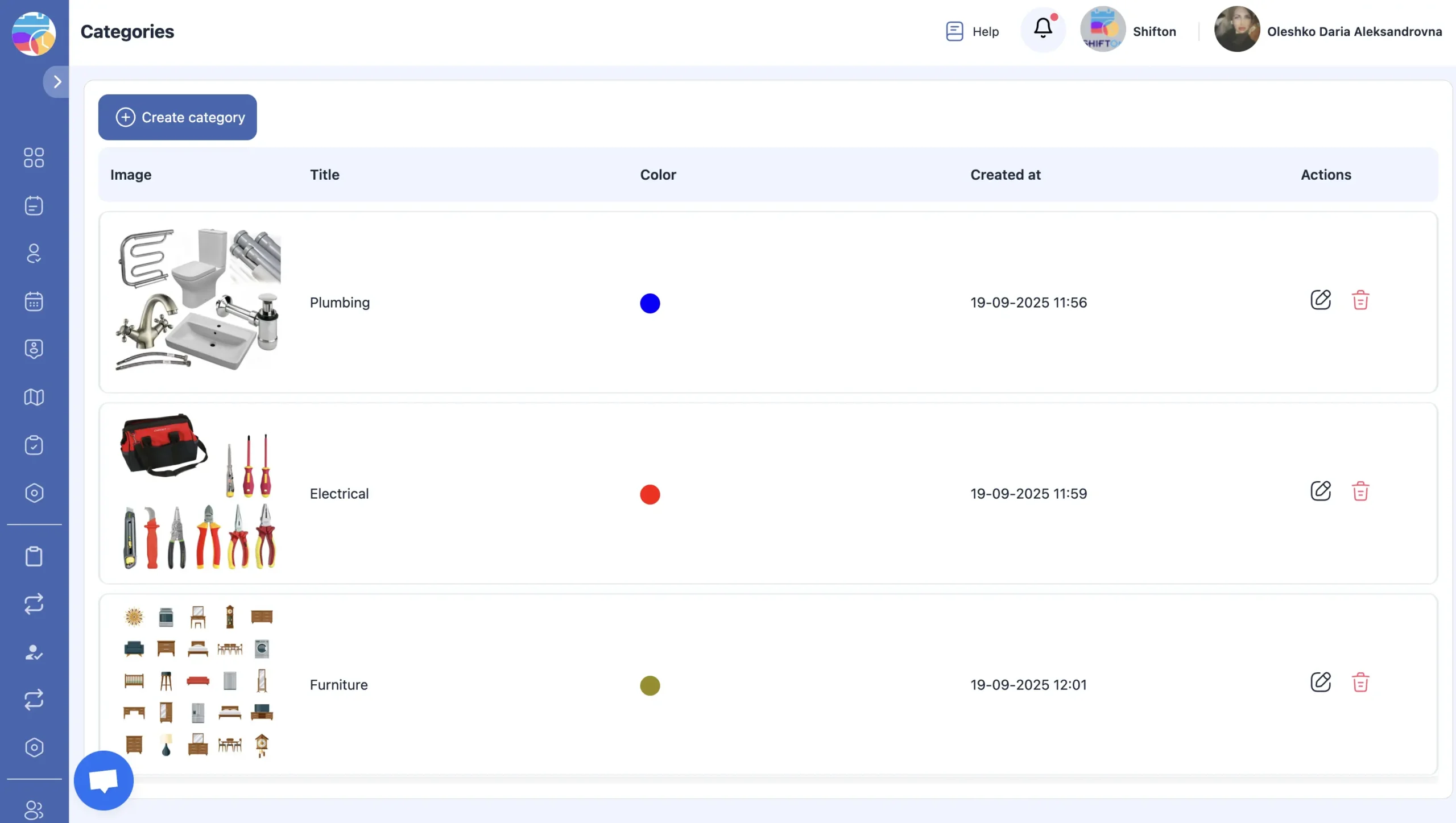

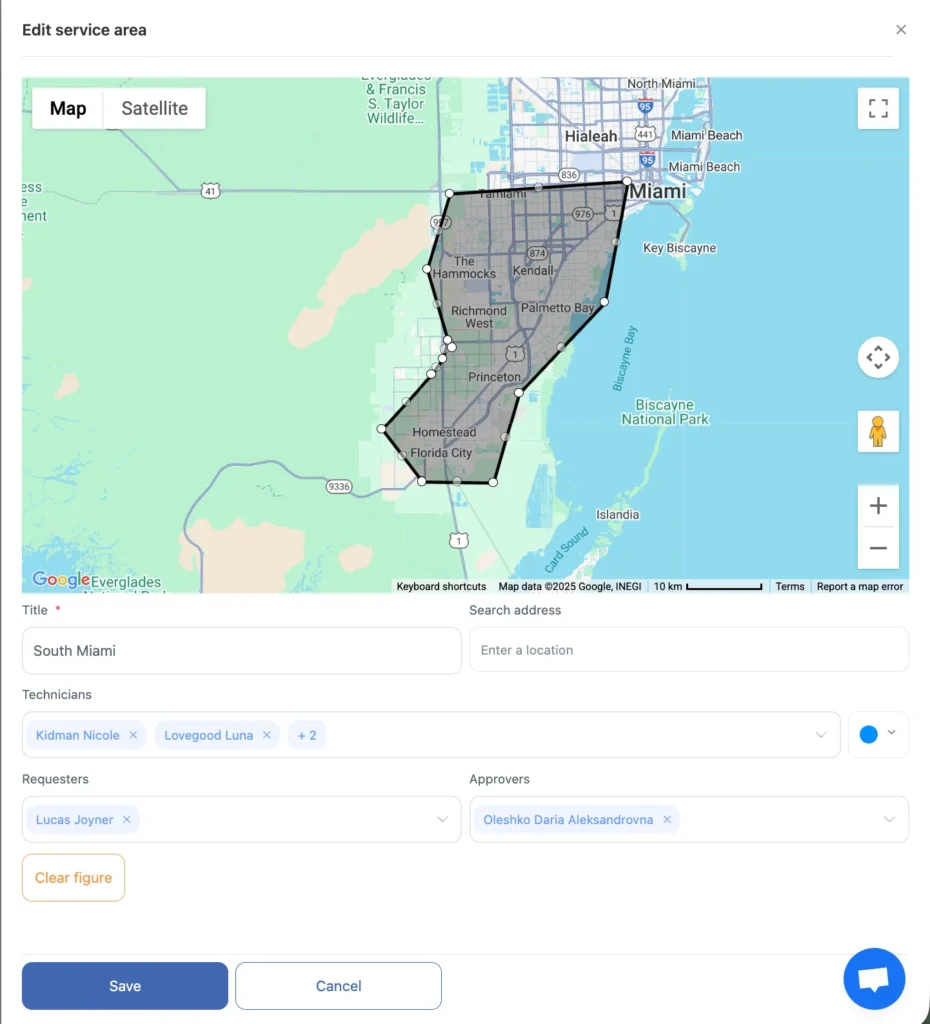

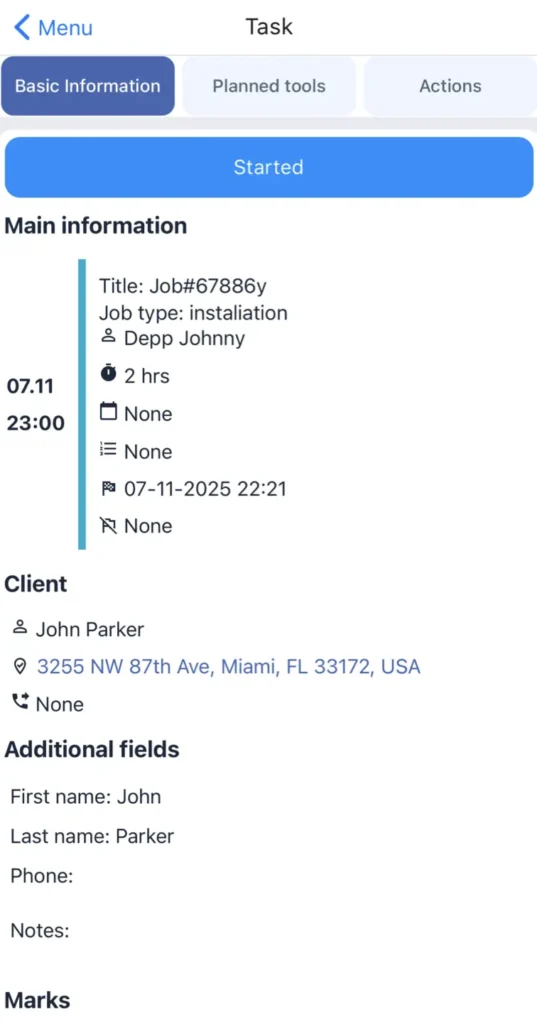

Running commercial laundry equipment service means handling site surveys, deliveries/rigging, utilities (water/steam/gas/electric) hookups, controller updates, bearing/seal jobs, belt/pulley work, airflow/vent checks, dryer ignition, lint/fire-safety checks, chemical pump calibration, warranty calls, and PM routes — across hotels, healthcare, OPLs, laundromats, and multi-housing. Teams need live visibility of who’s on-site, which machines/serials are in scope, what parts are issued, and where work is slipping. That’s why Shifton delivers a field service platform built for Commercial Laundry — clear statuses, precise assignments, and clean handoffs between dispatch, warehouse, technicians, and customer facilities.

English

English  Español

Español  Português

Português  Deutsch

Deutsch  Français

Français  Italiano

Italiano  日本語

日本語  中文

中文  हिन्दी

हिन्दी  עברית

עברית  العربية

العربية  한국어

한국어  Nederlands

Nederlands  Polski

Polski  Türkçe

Türkçe  Українська

Українська  Русский

Русский  Magyar

Magyar  Română

Română  Български

Български  Čeština

Čeština  Ελληνικά

Ελληνικά  Svenska

Svenska  Dansk

Dansk  Norsk

Norsk  Suomi

Suomi  Bahasa

Bahasa  Tiếng Việt

Tiếng Việt  Tagalog

Tagalog  ไทย

ไทย  Latviešu

Latviešu  Lietuvių

Lietuvių  Eesti

Eesti  Slovenčina

Slovenčina  Slovenščina

Slovenščina  Hrvatski

Hrvatski  Македонски

Македонски  Қазақ

Қазақ  Azərbaycan

Azərbaycan  Afrikaans

Afrikaans  বাংলা

বাংলা