Real-Time Control for Epoxy Sealing Operations

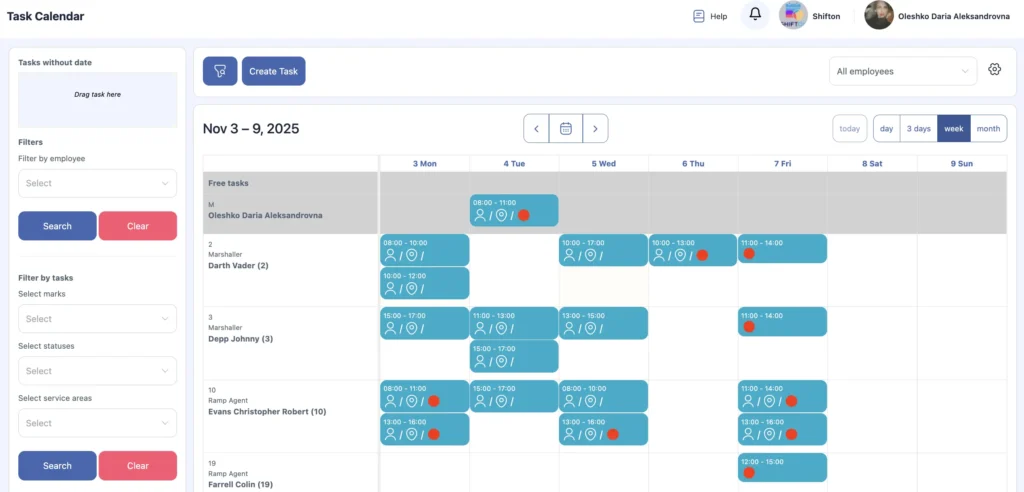

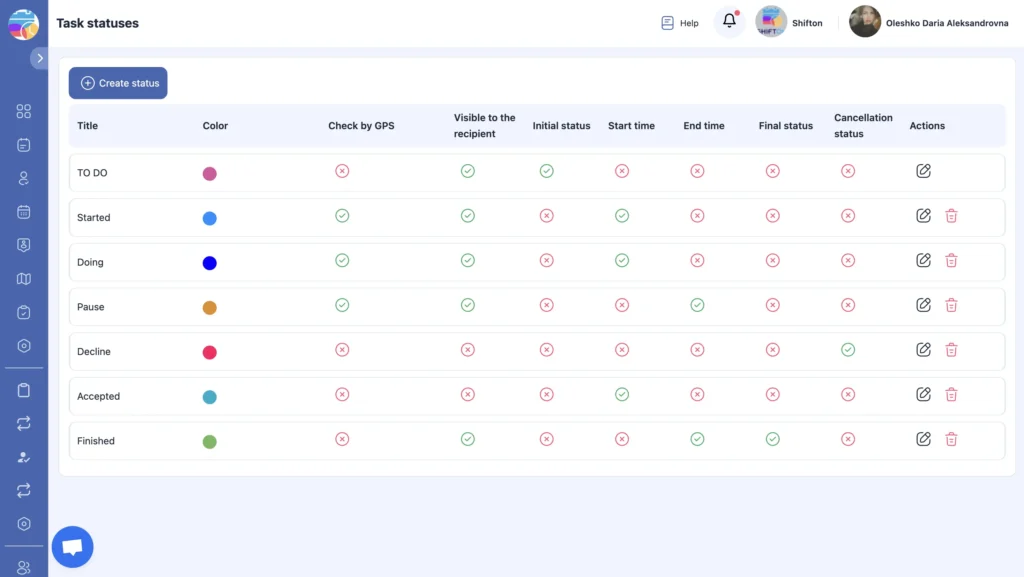

Running an epoxy sealing service means handling site assessments, moisture testing, surface prep (grind/shot-blast), crack/spall repairs, priming, mixing Part A/B within pot life, recoat windows, anti-slip additives, topcoats, and line striping — often across active facilities and tight downtime windows. Teams need live visibility of who’s on-site, which areas are prepped or coated, what materials are issued, and where work is slipping. That’s why Shifton delivers a field service platform built for Epoxy Sealing — clear statuses, precise assignments, and clean handoffs between coordinators, crew leads, and clients/GCs.

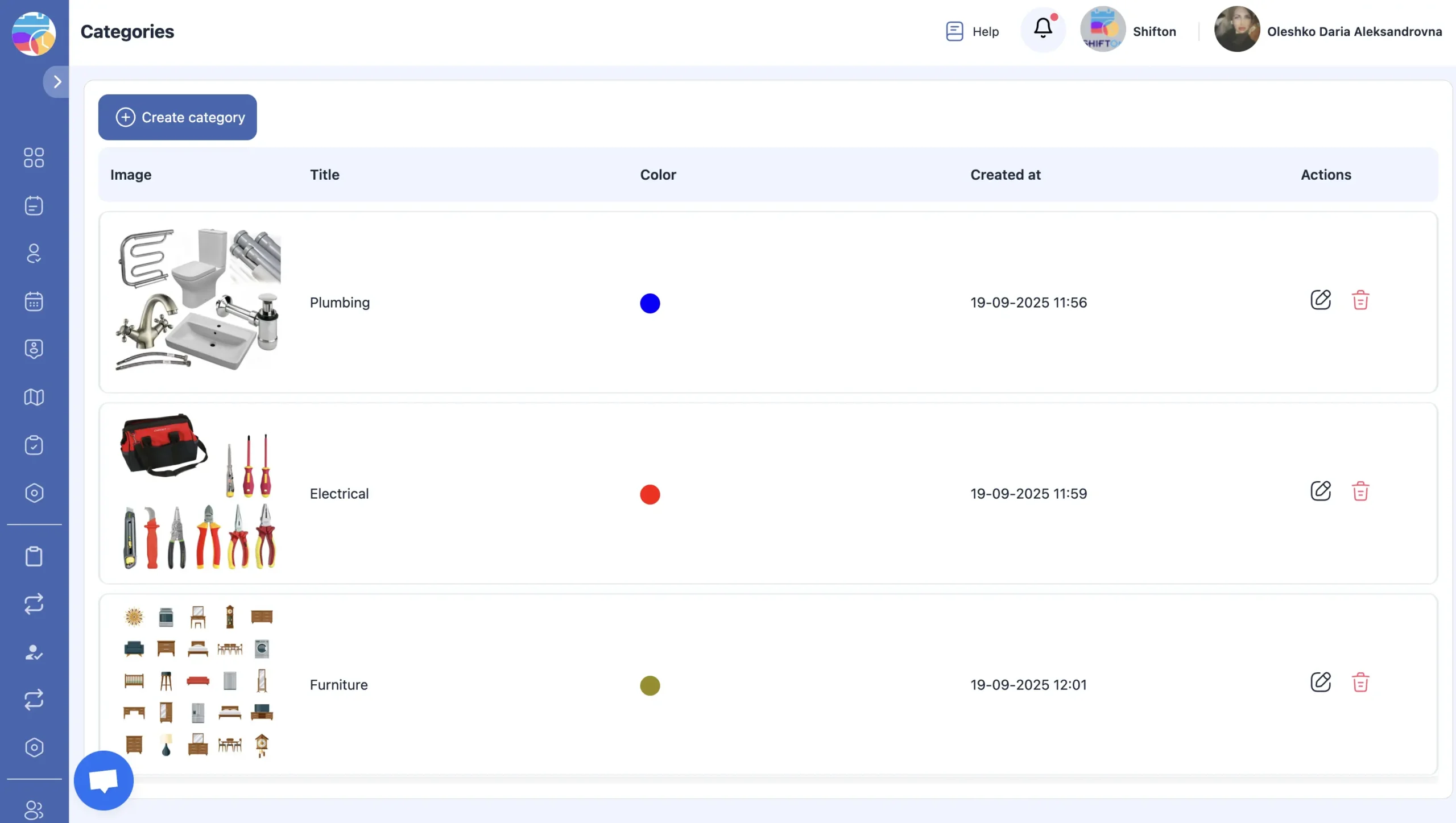

This epoxy-ready Field Service solution routes work orders, assigns the right crew to the right substrate and system (garage, warehouse, food service, healthcare), and tracks progress and time on-site in real time. Whether you’re doing decorative flakes, high-build industrial coats, or chemical-resistant systems, Shifton keeps tasks organized, auditable, and off messy chats.

With Shifton, companies cut rework, prevent missed steps (moisture test, profile, recoat timing), and provide photo-backed proof of work. You get operational control across properties, tighter compliance, and a better client experience.

English

English  Español

Español  Português

Português  Deutsch

Deutsch  Français

Français  Italiano

Italiano  日本語

日本語  中文

中文  हिन्दी

हिन्दी  עברית

עברית  العربية

العربية  한국어

한국어  Nederlands

Nederlands  Polski

Polski  Türkçe

Türkçe  Українська

Українська  Русский

Русский  Magyar

Magyar  Română

Română  Български

Български  Čeština

Čeština  Ελληνικά

Ελληνικά  Svenska

Svenska  Dansk

Dansk  Norsk

Norsk  Suomi

Suomi  Bahasa

Bahasa  Tiếng Việt

Tiếng Việt  Tagalog

Tagalog  ไทย

ไทย  Latviešu

Latviešu  Lietuvių

Lietuvių  Eesti

Eesti  Slovenčina

Slovenčina  Slovenščina

Slovenščina  Hrvatski

Hrvatski  Македонски

Македонски  Қазақ

Қазақ  Azərbaycan

Azərbaycan  Afrikaans

Afrikaans  বাংলা

বাংলা